Know About Turning Aluminium Part

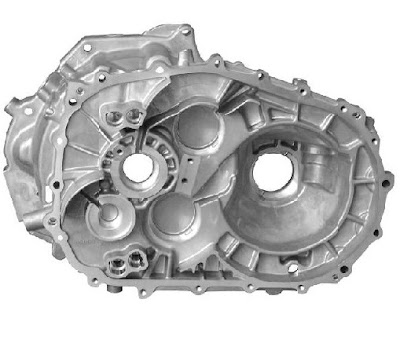

Through metal cutting, while using Computer Numerically Controlled lathes and used for precision machining to produce cylindrical components like pulleys, rods, hubs, etc CNC Turning is a process.

Through computer-aided machining software or well-known machine control units CNC Lathe, a machine tool is well programmed. According to the given technical drawing specifications to produce the final product a machinist program sets the needed cutting tools and the software-controlled machine. The CNC turning parts manufacturer is a reliable one.

Used for plastic machining, CNC Turning is the most crucial and simple process. After inserting the single cutter point into the material turning, it is utilized where the precision tool generates materials. Through a cutting tool that is parallel to the workpiece or applied either at the right angle to the axis, the cutting procedure is executed.

To form the flexible shapes of the material it is done through the weaker material or exercising pressure on the workpiece. The cut surface is formed as it results in rotation by executing the helical feed sometimes through Computer Numerically Controlled Lathe.

Until the precise dimension and depth are achieved the cutting tool is used. As far as the specifications and needs require CNC Turning for turning aluminium part can be done on both outside, inside, or sides.

On a machining center featuring U axis parts that are too large to cause difficulty and balance in rotating around one center point are working. With a speed range of 4,000 revolutions per minute and 46kW drive power, the turning length is about 1000mm between centers.

Into various shapes like simple plain surface, pointed, contour, radius profiles, tapered ends, fillet and curve with the threaded surface the CNC turning process cuts the plastic. To create rods, shafts, pulleys bushes, and much more these turning machining part is used.

To the most rigid materials like Stainless Steel, Aluminum, Nylon, Copper, Acrylic, Polycarbonate, Teflon, Brass, ABS, Titanium, PVC, etc, this turning process applies well that with the software program tooling can be controlled.

As compared to the CNC milling the CNC turning is more economical as by minimizing the design elements it reduces the cost of production. However, to the flexibility of designs, this also puts a limitation.

Comments

Post a Comment