Learn About the Processes and Advantages of Die Casting

In the initial stages, the components that were used were tin and lead

but with the introduction of alloys of zinc and aluminum, their use was tapered

off. Over the years the process has evolved starting from the low-pressure

injection techniques and automotive plastic parts to the

casting dies at pressures that can reach as high as 4500 psi. The processes are

very much capable of creating high-quality products that have excellent surface

finishing.

In creating a broad range of shapes die casting is an economical yet

effective process Compared to other manufacturing techniques it is considered

superior and is considered aesthetic and durable. Die has many benefits and

among them, the primary one is its ability to deliver complex shapes with high

levels of tolerance. Identical castings can be produced in mass before you are

required to add any new casting tools.

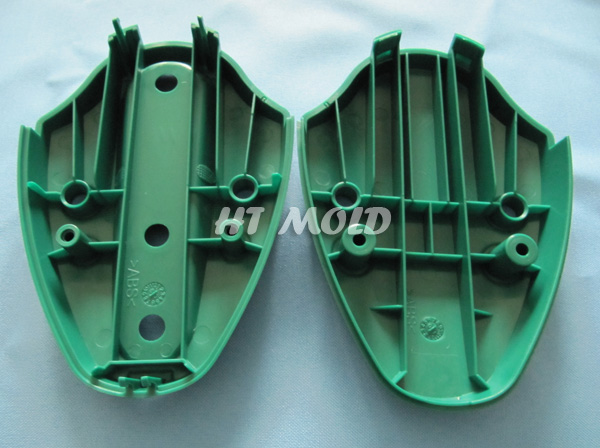

The high-pressure die is a manufacturing process of automotive

plastic parts in China. Into a steel or mold, casting machine aluminum in

its molten form is injected under extreme pressure, force, and speed to produce

parts of the desired design and shape. Universally the rating of casting

machines is in clamping tons.

Over others, there are many benefits of using the casting process. Die

casting produces parts with closer limits of dimension, thinner walls and it is

possible to speed up the process. With die labor and finishing costs are the

lowest. Through this process, you can cast coring in products created by automotive

plastic parts exporters in China.

Die casting is used when you require parts that are dimensionally stable

and durable. They are and maintain good tolerance levels and are heat resistant

and for any good machinery parts, these are crucial pre-requisites. Compared to

the parts that are made by other casting methods they are stronger and lighter.

They do not contain parts that are welded or bolted together, thereby immensely

enhancing their efficacy. Multiple finishing is another benefit that you can

achieve with casting.

Comments

Post a Comment